Technical features

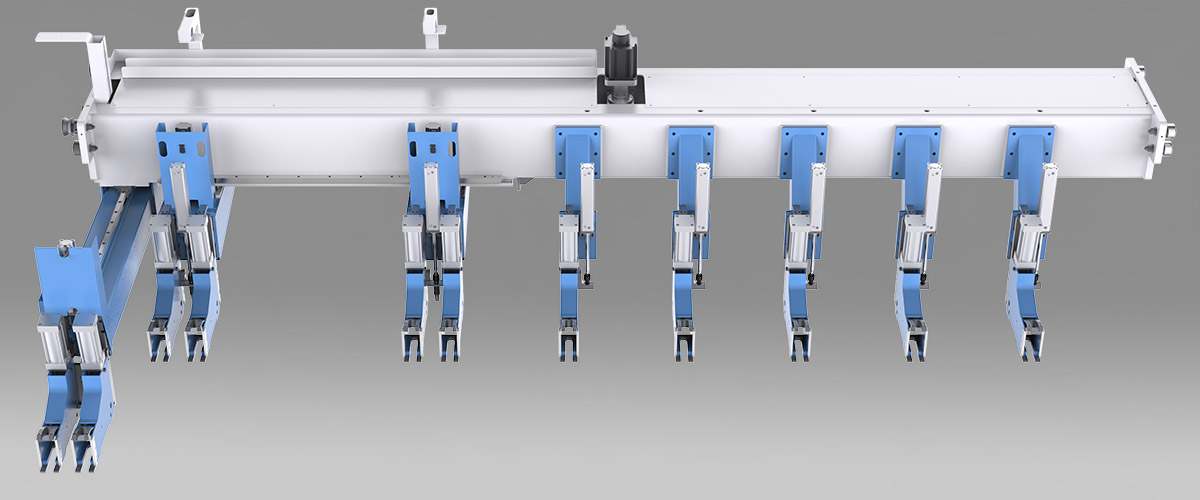

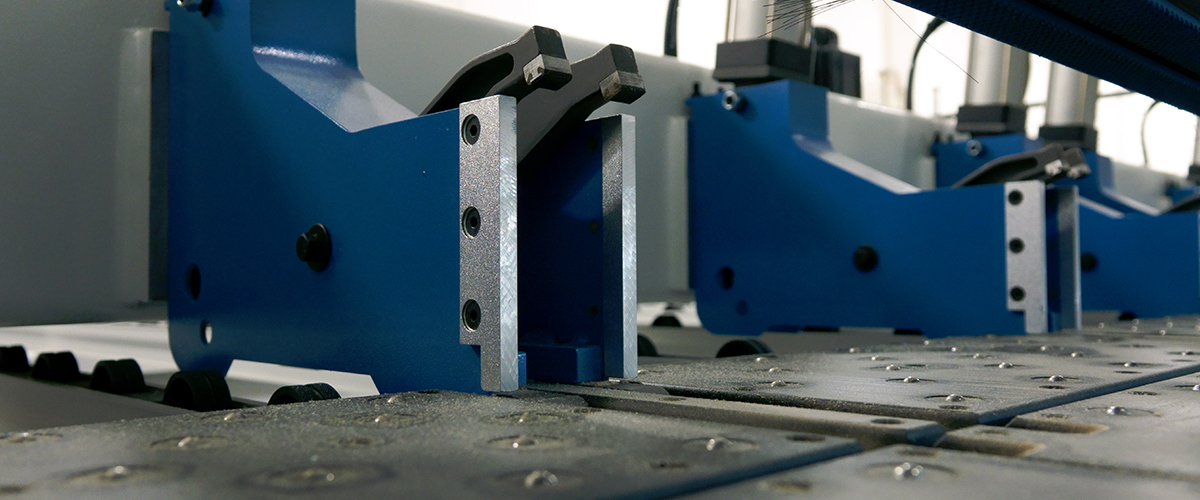

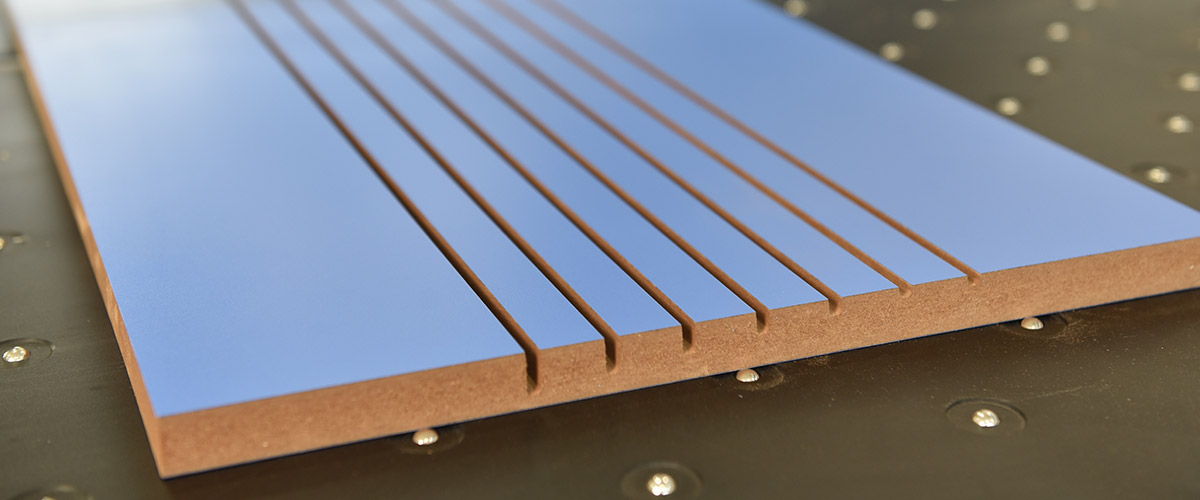

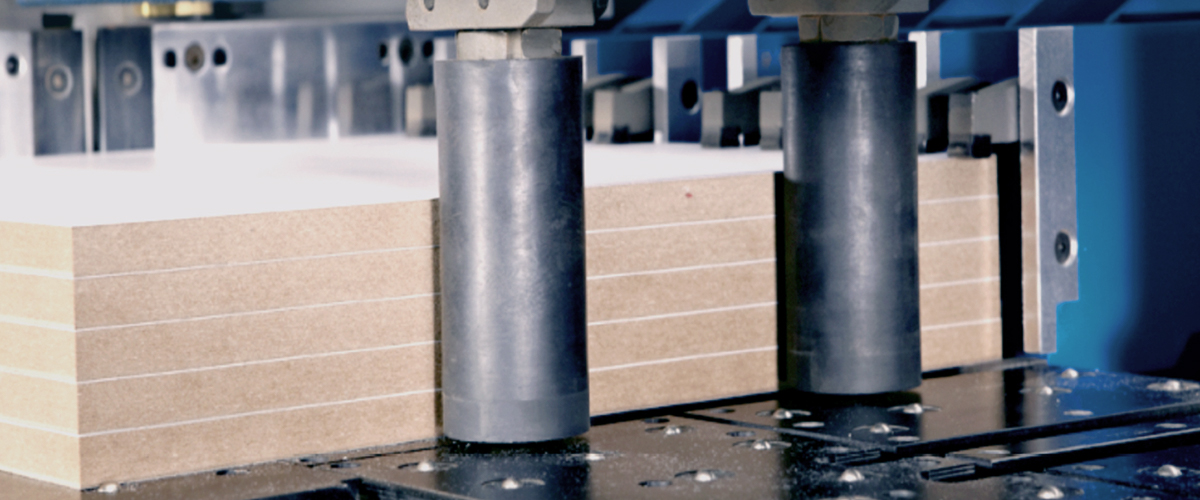

The new XY 450 L with 6 controlled axes has been designed to offer the maximum productivity and flexibility required by the market.Thanks to the sturdy mobile grippers on the X and Y axes, it allows you to work several panels of different sizes at the same time when performing cross cuts, considerably reducing the work cycles.

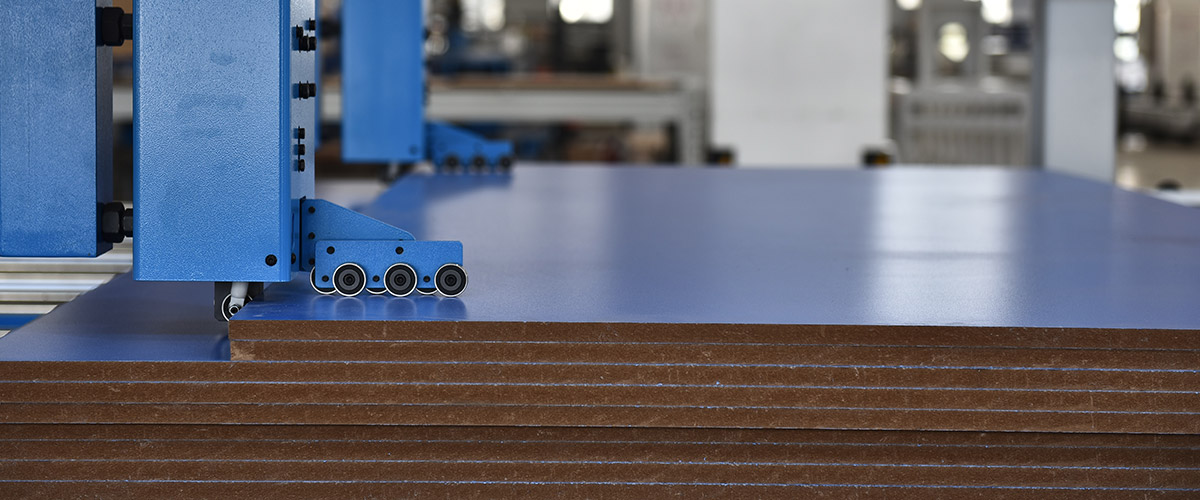

The secondary pusher is able to preload the panels taken from the lifting table and to work in masked time during the sectioning performed by the primary pusher.

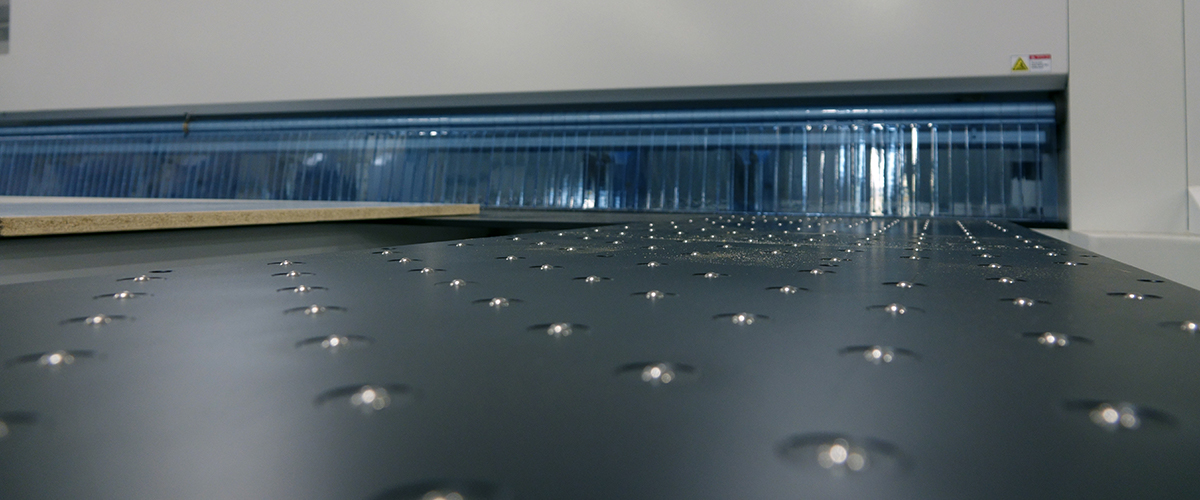

The massive lifting table is supported by 4 independent columns and allows to load stacks of panels up to 1200 mm in height.

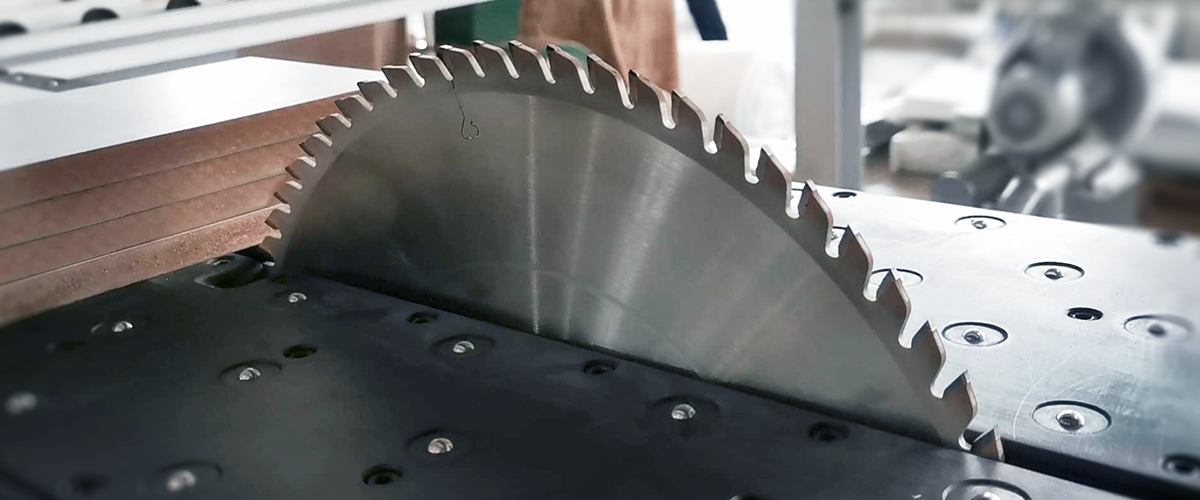

Extreme rigidity and sturdiness, units with high speeds (up to 200 m/min) make the XY 450 L the ideal machine for the most demanding companies.