Choose the CNC best suited for your needs

All CNC's and woodworking machinery

All CNC's and woodworking machinery

Designed for the company that needs compactness without sacrificing productivity

Speed, precision and robustness are its main qualities

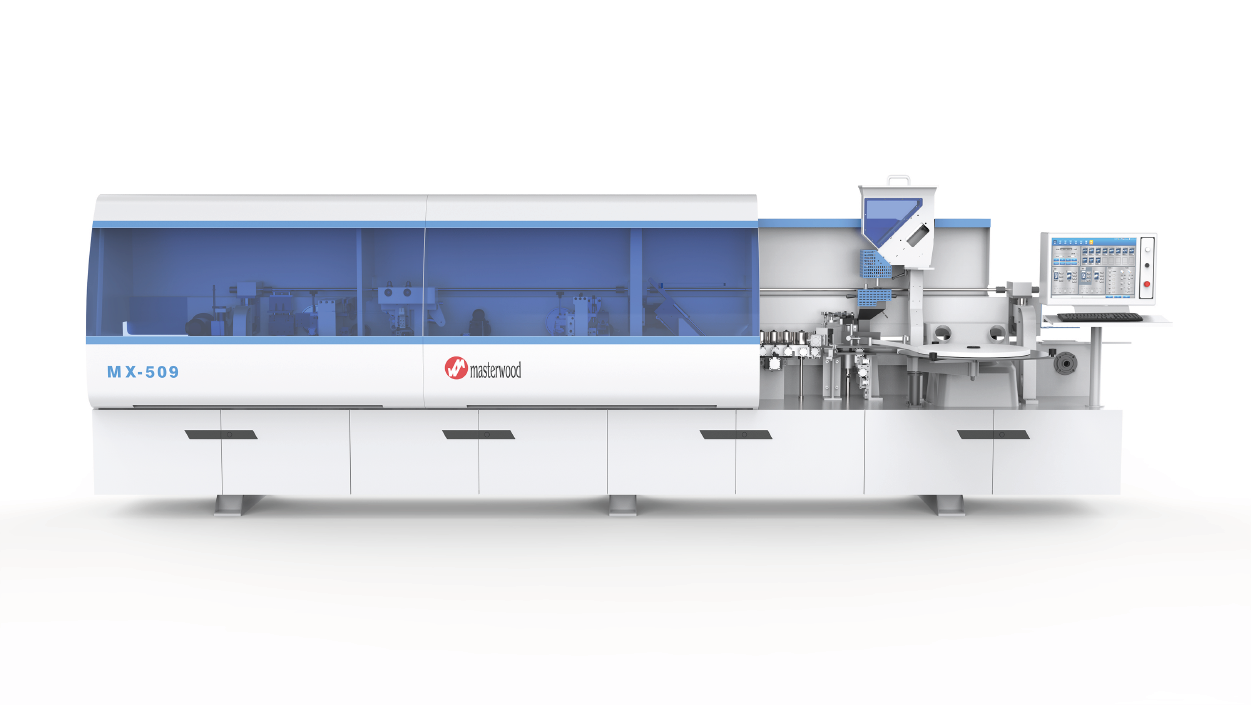

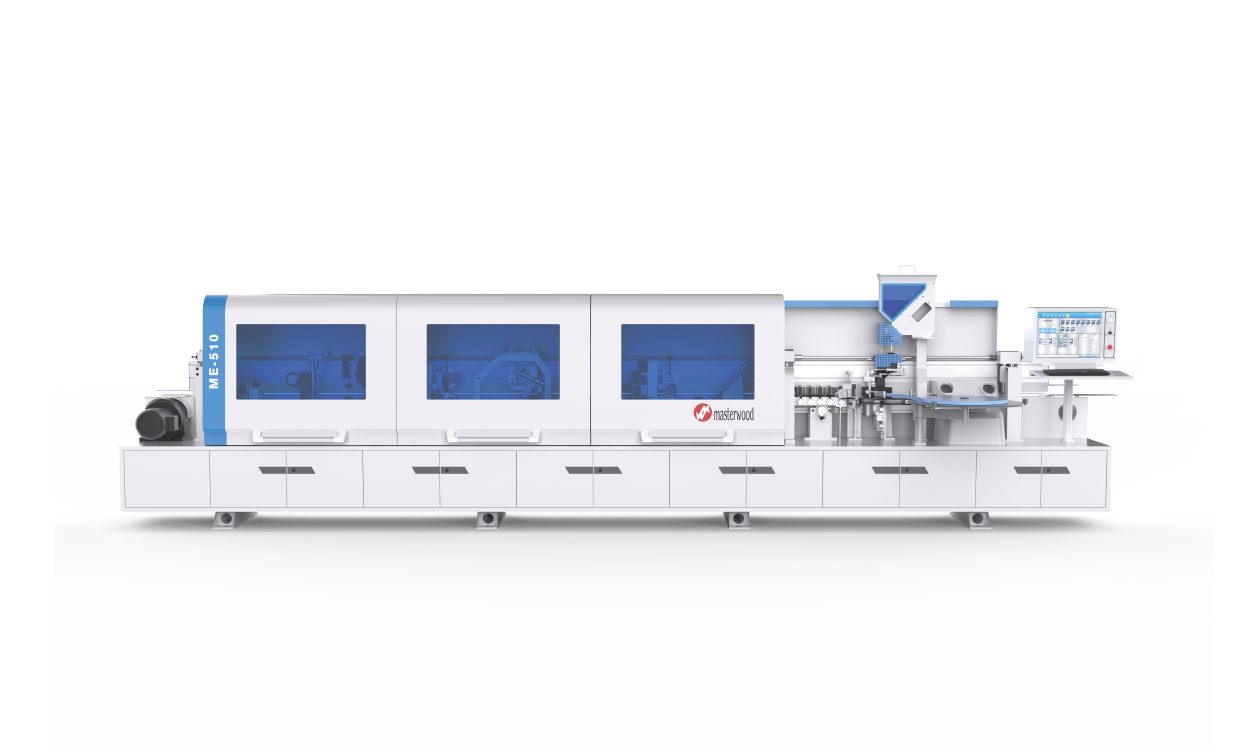

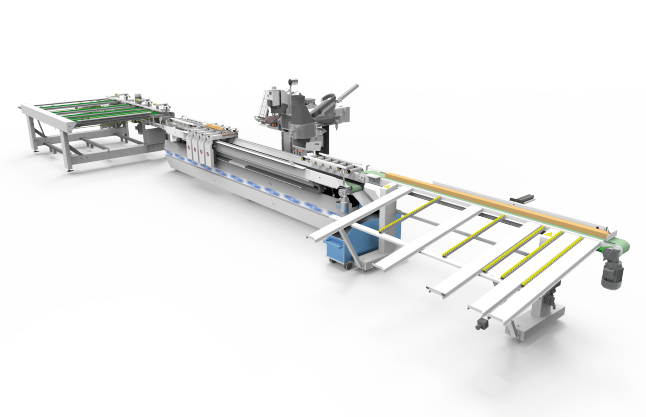

Our range of world-class edgebanders with controlled axes

A complete configuration for those looking for productive and qualitative performance without compromises

COMPACT SIZE, BIG IMPACT

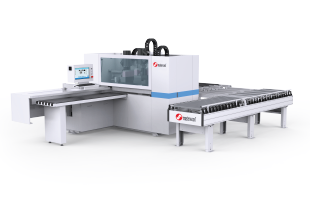

Controlled axes sliding table saw

The best solution for those looking for flexibility with maximum productivity

Perfect for those looking for high performance at high speed

High technology controlled axes sliding table saw

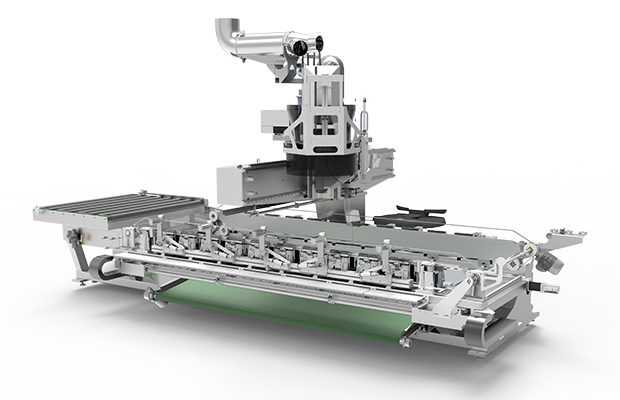

The machining center for high-speed drilling

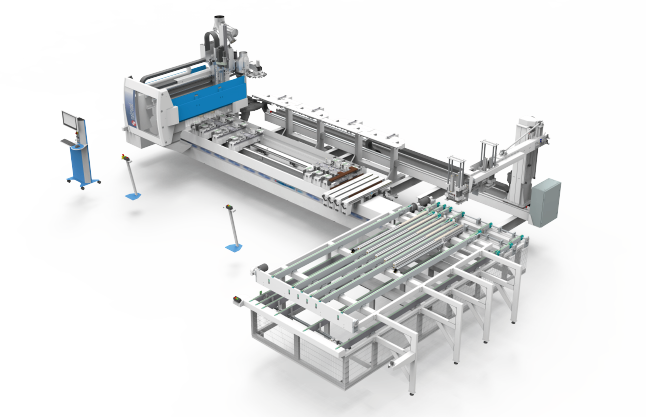

Maximum productivity for production lines and work cells

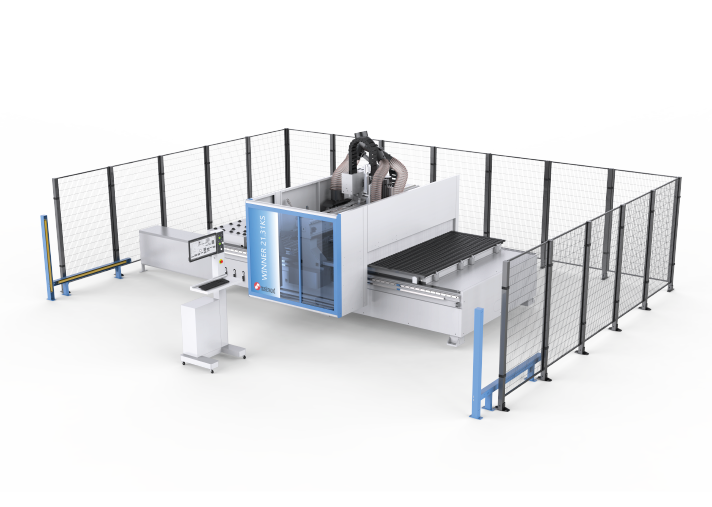

The compact machining centers designed for you

Winner 250 is the 3/4 axes CNC woodworking centre for those who decide to upgrade their fleet.

Winner 385 is the 5-axis machining center that easily fits any type of processing.

Project 485 is the 5-axis machining center for furniture manufacturers

High speed sawing in limited spaces

High productivity panel cutting

High productivity panel cutting automation

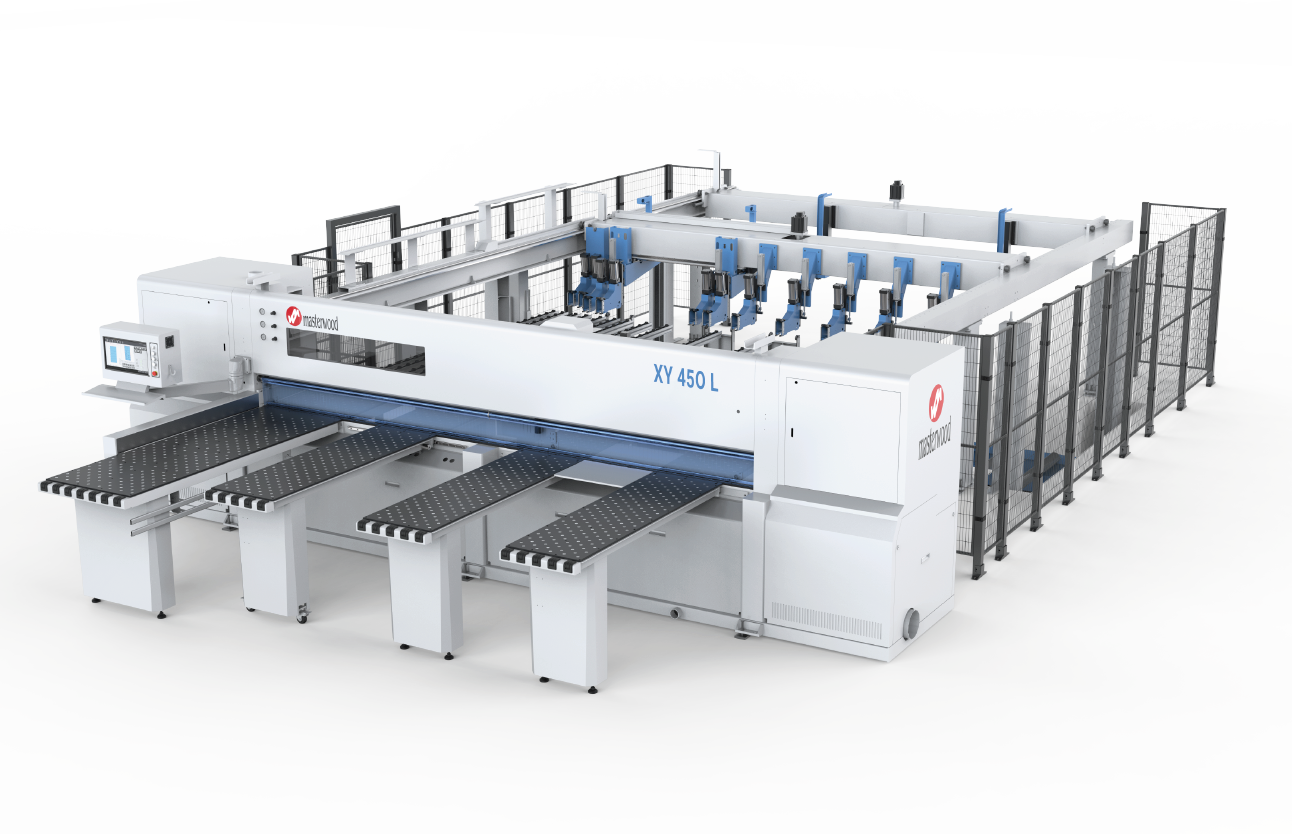

Automatic loading panel cutting centre for high productivity

Automatic loading controlled axes panel sizing centre

Project 250 is the 3/4 axes CNC woodworking centre or those who decide to upgrade their fleet.

After the great success of Project 350, Project 351 is born with machinable workpiece width up to 1550 mm.

Project 385 is the 5-axis machining center that easily fits any type of processing.

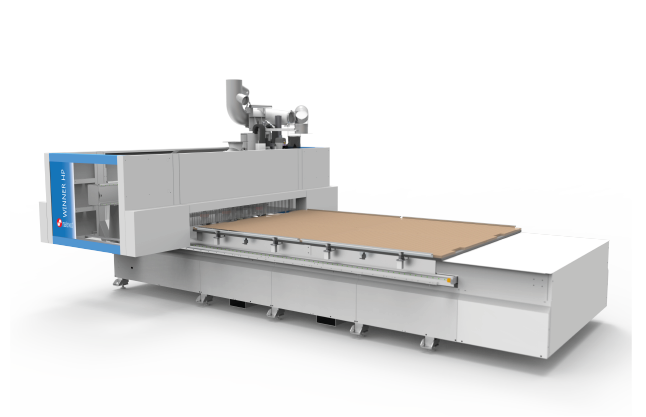

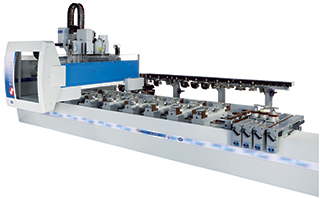

Winner HP is the 3/4/5 axes nesting working centre with high efficiency Matrix worktable

Project 470 is the 3/4 axes machining center for panel and solid wood processing.

Project 485 is the 5-axis machining center for furniture manufacturers

Project 565 is the 5-axis machining centre for those who point at the highest standards in all types of panel and solid wood machining.

4 WIN is the 3-axis machining center for processing of window and frame elements according to the prefinished technique.

4 WIN is the 3-axis machining center for processing of window and frame elements according to the prefinished technique.

The working cell dedicated to mass production of assembled doors assembled with a productivity of up to about two doors per minute.

Automated solutions for jambs and frames

Project Doors is the flexible working cell for assembled doors.

The Nesting KS series consists of 3-axis machining centers for "nesting" operations, suited both as "stand-alone" CNC or part of automated production lines.

The Nesting M series consists of 3-axis machining centers for "nesting" operations, best suited to be part of higly automated production lines.

The Nesting M5 series consists of 5-axis machining centers for "nesting" operations.